[We successfully fulfilled our promise and sent out the first batch of 526 AYA NEO]

Hi, everyone, do you remember your first impression when you heard about my name and some changes in AYA NEO?

Whether it’s confusion or worry, whether it’s trust or support, after more than two months of hard work, we have proved that AYA NEO’s new team is trustworthy.

After overcame many difficulties and pressures, we sent out all 500 of the first batch for IGG backers. Backers around the world have successively received AYA NEO, and shared photos/videos on YouTube, Twitter, Discord and other communities.

While feeling everyone’s joy and enthusiasm, we also received some feedback on some of the defective products of the first batch. From the information that has been obtained so far, a few of the first batch of AYA NEO have some problems. My friend @Generu helped me sort out most of the problems on Discord, thank him!

As a start-up brand, I think it’s the right approach to respond to all problems without fear of difficulties. Therefore, after a period of time after the first batch delivery, we have sorted out most of the problems and solutions internally.

In-terms of hardware problem, it is mainly the following parts:

-

After using for a period of time, traces of glue may appear in the four corners of the screen onsomedevices.

-

Some devices may experience friction between the fan blades and the back caseat certain angles.

-

A small mount of the units have serious back-light bleeding.

-

The seams of some parts of the caseare not neat.

-

Screen color calibration problem.

-

The speaker sound is too low.

-

The quality of the printing on the buttons is not good.

In the half month since shipment, we have further researched these problems, most of them have found a solution. In fact, some problems have actually begun to be solved when I took over AYA.

-

Traces of glue in the four corners of the screen

Causes of problem: There are two possibilities for the glue problem on the screen. One is the bonding problem between the screen and the glass, and the other is because of the structure of the mold.

Improvement for the second batch: At present, we are fine-tuning the structure of the mold, mainly the case and the middle frame. Ensure to avoid them putting too much pressure on the screen.

Solution for first batch: At present, our solution to this problem is to provide overseas users with a new screen (including the case) to replace or ask the user to send it back to AYA, and we are responsible for the replacement of the screen.

-

Friction between the fan blades and the back case

Causes of problem: In fact, before the production of the IGG version, we have remade the mold of the heat dissipation module and re-ordered a new fan. Among the first batch of users of the IGG version, there are still a few people who have encountered fan problems. After investigation, we believe this is mainly due to two possibilities: the first one is that a small percentage of these are due to problems that occurred during the assembly process that were not detected, and the second is that the fan has encountered quality problems.

Solution for first batch: At present, our solution to this problem is to instruct users to fine-tune the adhesive of the fan, or we will send the fan to the user, and the user replaces it by themselves. If you can’t solve it, you can send it back to AYA for repair.

-

Back-light bleeding

Causes of problems: this is a relatively common thing in IPS display panel, but we will also try to reduce it as much as possible.

Improvement for the second batch: We are adjusting the mold structure to reduce back-light bleeding.

Solution for first batch: If the back-light bleeding is particularly serious, you can send it back to AYA, and we will adjust the screen for you.

-

Seams on the case

Causes of problems: this is the mold itself has some defects.

Improvement for the second batch: We are adjusting the mold to achieve better case quality.

-

Displaycolor calibration

Causes of problems: The quality of the screens we use are good, but every screens has its native color characteristics which caused this problem.

Solution for first batch: we will provide color calibration profile for users to adjust the screen themselves.

Improvement for the second batch: We will pre-apply this profile in the color calibration of Windows.

-

The speaker sound is too low.

Causes of problems: This is because of the team in the past did not design the sound chamber for the speaker when designing the mold, so the speaker sounded directly without optimization of the sound chamber.

Improvement for the second batch: To solve this problem, we started looking for a new and better speaker more than a month ago and decided to modify the internal structure of the mold to add a sound chamber to the speaker. To be honest, this is not an easy task, because it is very difficult to add the sound chamber in a limited space, but as the saying goes, "There is nothing difficult in this world, only a dedicated person can do it." I am happy to tell you that we have done it, and we have chosen a new speaker with good sound quality for AYA NEO. It also adds a sound chamber to it, and now AYA NEO will has a very good speaker. You can use it to experience first-class game sound effects.

-

Low printing quality on buttons

Causes of problems: When I took over the project, the buttons have already been produced and the printed. Not much time left for me to improve.

Improvement for the second batch: Since the results is not good, I decided to remake a new mold for the buttons, and the mold will solve this problem by using the "two-color mold". The color on the buttons is no longer printed but will be the color of the material itself, so the color will not fade after long-term use.

To be honest, in the past two months or so, we have faced more problems than you think. There are many problems that I did not write on IGG updates but are quietly solving them.

After the first batch of AYA NEO been shipped, I felt sorry and ashamed to see some of my friends encountering problems. Although there were some issues that already existed when I took over, but as the new CEO, I need to be responsible for the brand and the users, so during this time, especially after shipping out the first batch of AYA NEO, you can see that I wrote IGG update less often because our team spent a lot of time to solve these problems. We contacted with new manufactures, new suppliers, we solved a lot of problems and made a lot of decisions with one goal: to build the best Windows handheld for our friends who support us.

To achieve that, we need more time to improve the second batch of AYA NEO and gradually turn it into a relatively complete product in my mind. Although the product was not originally defined by me, as the CEO, I have the right and obligation to make it better.

My friends, in the next month, I set the following goals. I will use all the energy and time of me and the team to catch up and build a better product in our minds. I will continue to work hard, and I will never give up until the goal is reached.

Well, let's show you what we're going to put on.

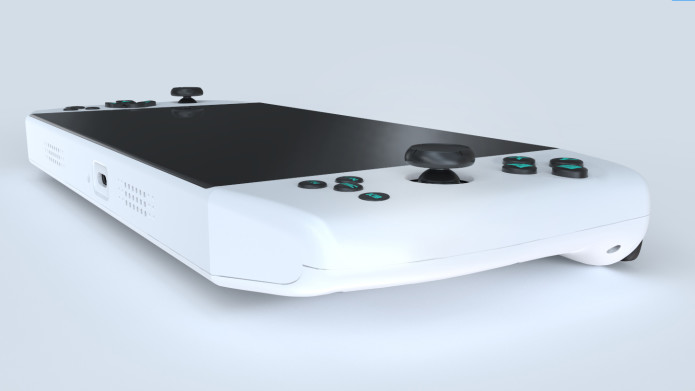

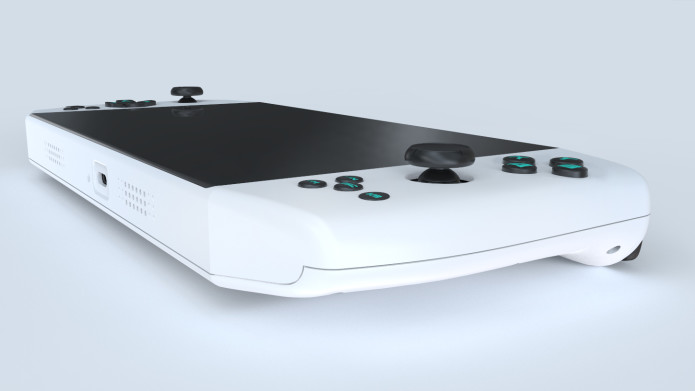

[Adjustment of the case mold]

I will make a wide range of corrections and adjustments to the entire case mold to solve a large number of detailed problems, including:

-

Solve the difference between the upper and lower parts of the case and enhance the handfeeling.

-

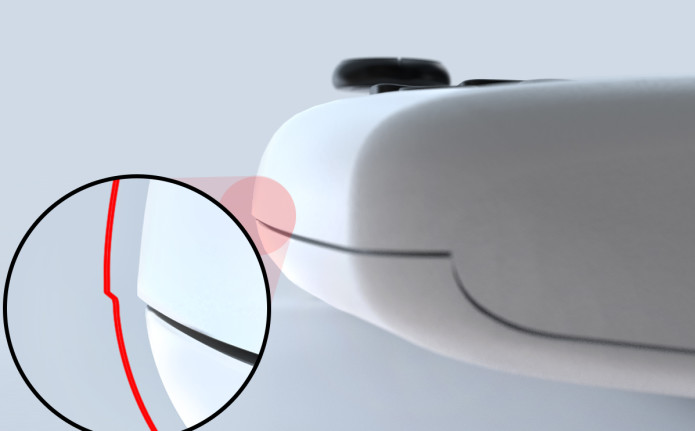

Add a split line among the seams to enhance the aesthetics.

- Before

- After

-

Increase the height of the volume button to make it easier to beblind pressed.

-

Improve the internal structure to solve the difference in the left and right edges of the front case.

-

Reduce the height of the battery compartment inside the back caseto improve the support of the back case.

- Before

- After

-

Remove the original snap design at the top and bottom of the case connection to enhance the aesthetics.

- Before

- After

-

Adjust the glue feeding position near the air inlet to optimize the mold and reduce defects.

- Before

- After

-

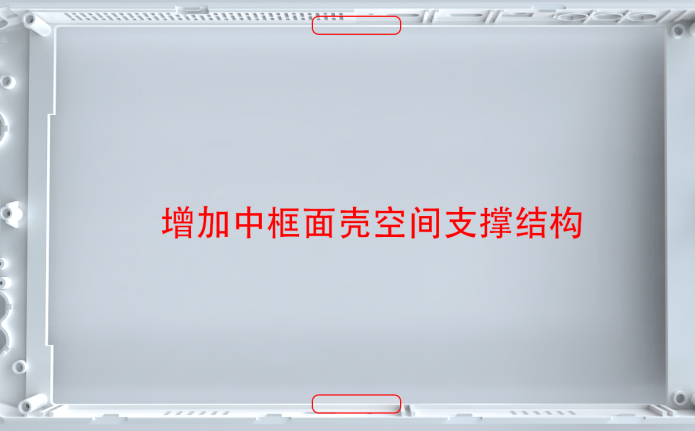

Increase the support structure between the case and the aluminum frame in the middle to enhance stability.

[Huge changes in buttons]

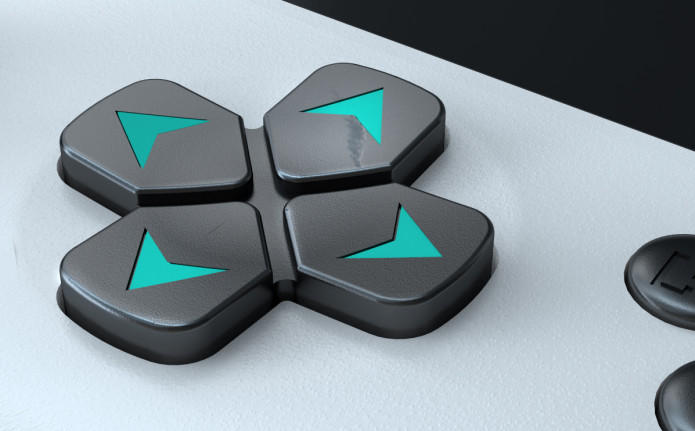

For a handheld, the feel of the buttons is very important. Although AYA NEO already has a good press feeling, I hope to keep improving and take it to the next level, so huge changes will be made to the buttons.

-

As mentioned earlier, we will remake a set of "two-color molds" for the buttons. This set of molds can solve the problem of printing qualityof the buttons, because it will be produced with the color of the materialitself, rather than printed. The aesthetics and durability are greatly improved, and the color will not fade. Tthe font of the text on the buttons will also be adjusted to use a better-looking font.

-

We will adjust the feel of the buttons. In the past, the buttons used "metal dome". We will optimize it and replace it with "conductive rubber". The buttonswill feel a bit like "Switch Pro Controller".

-

We will optimize the feel of the d-padbyoptimizing middle axis, so that it has a better experience and feedback when playing fighting games.

-

Because it is a brand-new mold, thedamage onbuttons caused by the original mold will not be existed anymore.

[More functional updates and new appearance for the joystick]

We will provide a new and distinctive appearance for the cap of the joystick. And more important, we will provide more functional updates to the joystick firmware in the future and will add custom functions to the official AYA Neo software.

- The production line of our brand new joystick supplier factory (the picture is not our product).

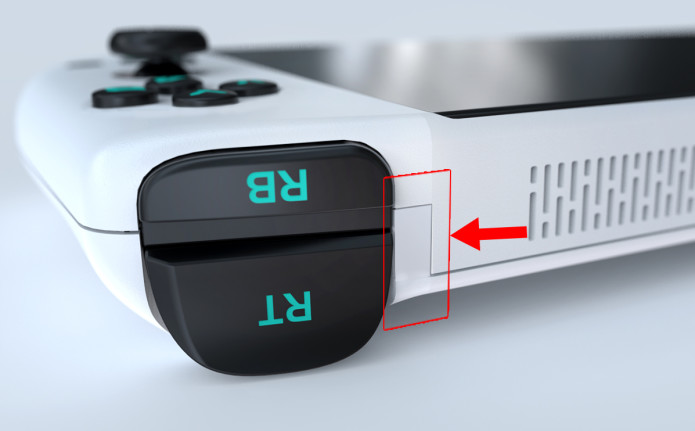

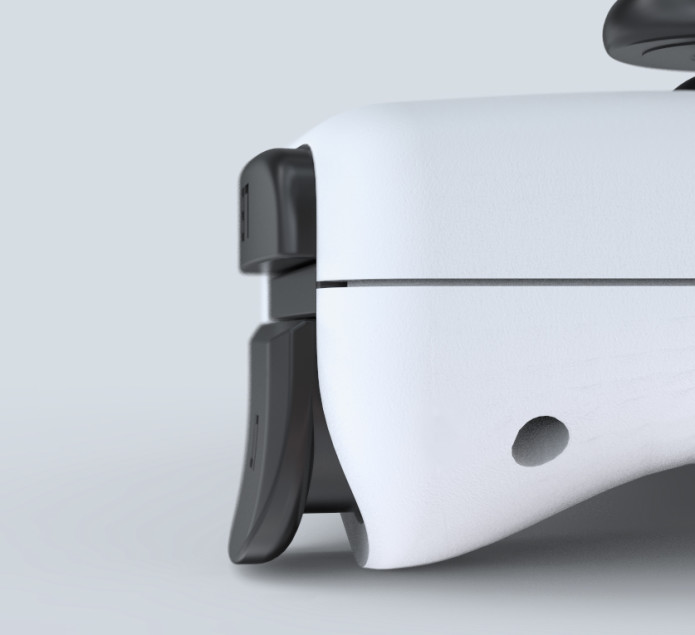

[Analog shoulder buttons]

Many friends hope that AYA NEO has analog shoulder buttons. Now it is here. I am also a racing game enthusiast, so I am not satisfied with AYA NEO’s LT/RT buttons. This time we will develop an analog one for it. From then on, we can enjoy "Horizon 4" and other racing game masterpieces.

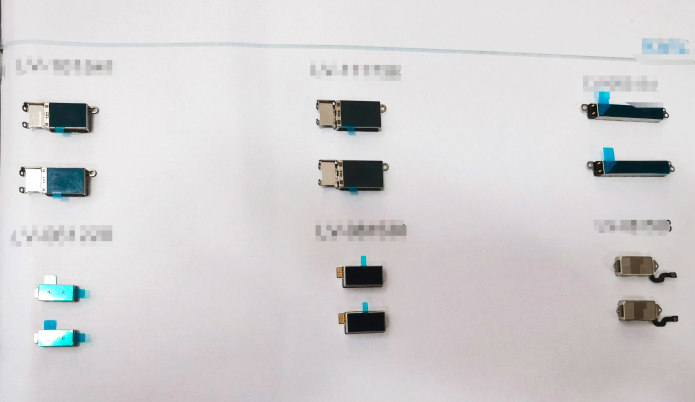

[Linear resonant actuator for AYA NEO]

That’s right, another update beyond your imagination. I am not satisfied with AYA NEO’s original vibration function just like you.

We will develop a new LRA (linear resonant actuator) for AYA NEO so that we can enjoy the delicate vibration. We will explore more uses case for LRA in the future.

- We chose a brand new Linear resonant actuator for AYANEO.

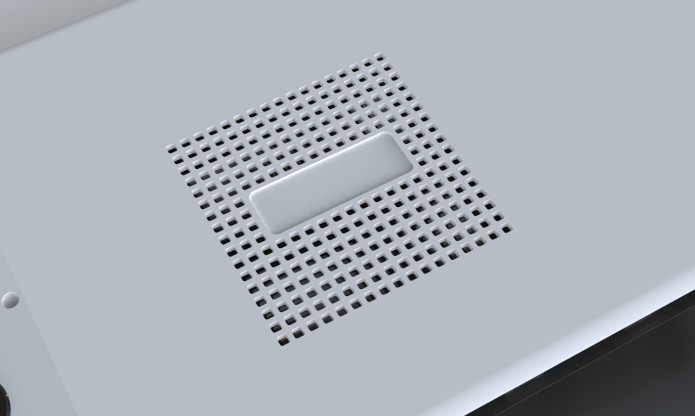

[Speakers with sound chamber]

Handhelds need excellent appearance and good operating feel, and they also need to have a perfect sound quality experience to bring a stronger sense of immersion. After one month of research and development, we will bring mainstream level sound experience to AYA NEO, and the game experience will be greatly improved.

- We are testing the effect with 3D printed samples.

Click here to view the test results of AYANEO's new speakers.

Please note: this is not the final result, the final result will be better.

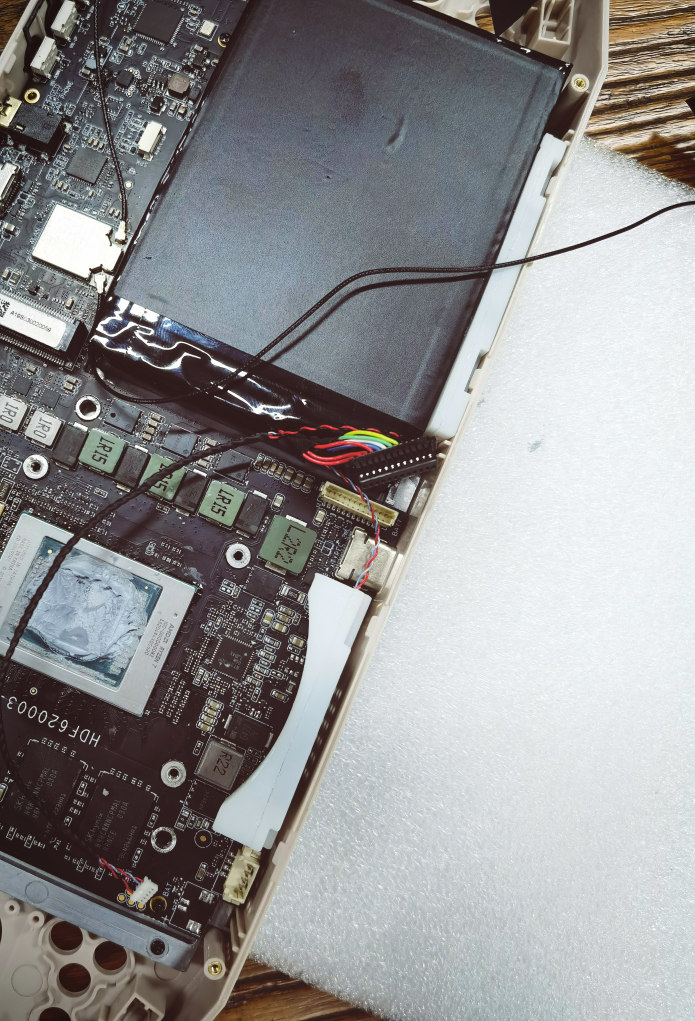

[Re-optimized the heat dissipation module and fan]

In the first batch of the IGG version, we have optimized the heat dissipation module and fan, and in the second batch, we have optimized the mold of the heat dissipation module again and continued to improve the matching between the fan and the heat dissipation module/case. We will also place higher requirements on factory assembly and quality control to reduce the probability of fan problems.

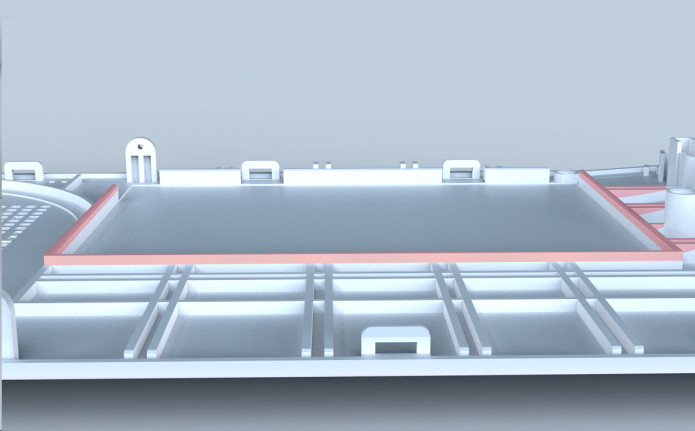

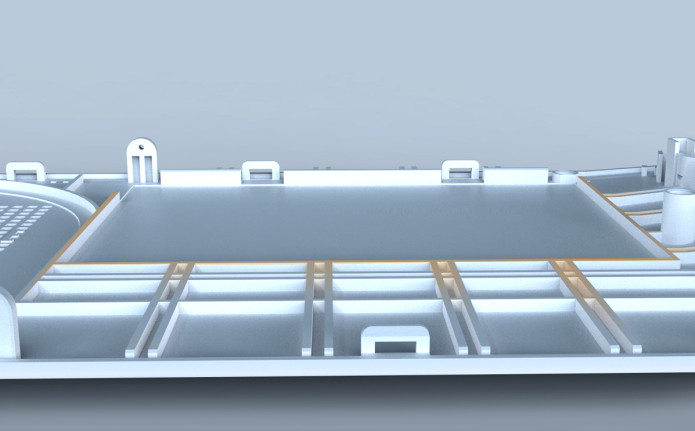

[New middle aluminum frame which will better supporting the screen and the case]

The original aluminum frame was not perfect, which would bring about a series of chain reactions, so we changed the factory, re-made a set of molds. New and higher standard are placed on its firmness and flatness. The new middle aluminum frame can better support the screen and case, which can reduce the possibility of back-light bleeding and screen glue leakage.

The above changes based on molds and buttons will be a very large project. We have entirely re-designed AYA NEO's controller and structure, and the controller PCBA has to be re-made, too. All these not only requires more cost investment, but also requires more time. Frankly speaking, I can choose not doing these things to reduce costs, but I am a player, and I am not satisfied with my own product. I can feel everyone’s expectations on it. When I have the ability to optimize it, I am willing to improve it regardless of cost, so as to live up to everyone's expectations, and this in itself is also my attitude towards branding and product making. I hope that AYA NEO can make everyone feel the ultimate pursuit of our team.

[PCBA modification is progressing smoothly, new WIFI module from MTK]

Our R&D team has been modifying the PCBA. As mentioned in the previous IGG update, we modified the PCBA because INTEL’s AX200 is out of stock, so we had to change the PCBA’s WIFI module to M.2 specifications. The PCBA’s modification work is very smooth (expected delivery on July 25), but we learned that the AMD RZ608 chip will be delayed, and the delay may be a bit long, so we have been looking for a solution in the near future. Fortunately, we found MTK's WIFI module is available, and it is directly supplied by MTK, which will be available at the end of July.

In view of the fact that there are too many changes mentioned above, it takes more time, especially the production of some molds which takes more than 4 weeks. Therefore, after collecting all the information, the key time nodes we internally evaluated are:

* The production of two-color molds for buttons takes 4 weeks.

* The full process of redesign, trial production, small batch production, and mass production of the controller PCBA will take 45 days.

However, we currently plan to take the risk of losing a large number of PCBAs, to skip the small batch production phase and directly into the mass production phase from trial production phase.

If this goes well, we will save nearly 20 days.

* It is estimated that the modification of the case mold will take about 20 days.

* The remake of the aluminum frame mold takes about 20-30 days.

Based on the above analysis, our preliminary estimated time is:

* Complete new components preparation for all 2000 units on July 30.

* Start assembling in early August.

* Shipment will begin by mid-August.

Important note: The above time needs to be based on the premise that all the above modifications are successfully completed without any problems.

If one of the modifications is delayed, the shipment will also be delayed accordingly.

Compared with our original commitment to start shipping in the first week of July, the shipping time of the second batch has indeed been delayed, which is affected by two factors. The first is that PCBA and WIFI chips cannot be delivered until the end of July, the second is that we have made new requirements on the product and spent a lot of money on modifications.

I hope everyone can feel our sincerity, because to complete the above improvements, a large amount of money is needed and the cost of each device has exceeded the funds we collected in the initial stage of crowdfunding (and these features hadn’t be promised at the first place), but we will not charge you extra fees.

This project is for the dream of all the handheld enthusiasts. In order to build the best Windows handheld in the world, we must not only provide the best products, but also be willing to provide the best services, and willing to upgrade our products again and again. When we saw every backer excited and happy for the AYA NEO they received, the time, energy, money and feelings we put into it all seemed worthwhile at that moment.

Talk about a little thing, maybe you will feel our determination to create a quality product:

In our company's warehouse, there are more than 3,000 sets of cases and controller PCBA, vibration motors, speakers, and more than 5,000 sets of buttons.

In order to provide you with better products, when I decide to complete the above work, it means that the above component will be scrapped, and this is also a large amount of money.

For a better product, it's not a big deal.

In addition, I also prepared two follow-up plans:

-

If anyone is dissatisfied with the delay, welcome to apply for a refund. We will provide refund service until July 3. Starting from July 4th, refund applications will not be accepted because we need to prepare componentsfor production.

But it needs to be reminded that when we complete the above work, AYA NEO is already in a brand-new form. It is very likely that its price will change, and you will never get it at the original crowdfunding price.

In addition, our PAYPAL account has just been applied and some transactions have not been verified, so it is currently in a locked status and can only receive payments, so we need to wait for PAYPAL to unblock our account before you can get a refund, which will be determined later.

-

At the end of July, if PCBA and WIFI moduleare ready, but other works encounter problems, it may take longer to prepare, I will start a temporary production plan according to the situation, if someone does not want to spend more time waiting, we can produce it in advance for them with the original products which may still have some problems. I will continue to evaluate whether to start this plan.

In addition, for the first batch of users, I will provide a welfare policy in the future to return your support and make up for the regret that you did not get a more perfect device that I built.

In short, AYA NEO will provide everyone with the best products and best services. The AYA NEO team and AYA NEO brand will continue to grow and strive for the best Windows handheld brand in the world.

Please remember that all our efforts are due to you, our backers.

We have the same ideas and dreams.

We are all players.

Welcome to leave your opinions and suggestions in the comments. We are very happy to have your support and interaction. I will read every comment carefully.

{/if}

{/if}

{/each}

{/each}

Recently Used

My Collection

Emoticons uploaded by everyone

{each $comments as $comment}-

{if $comment.author.verify_identity}

{/if}

{if $comment.author.verify_identity}

{/if}

{if $comment.reply}

-

{each $comment.reply as $reply}

{/if}

{/each}

{if $comment.is_top}{lang_comment.top}{/if}{$comment.author.username}:{@$comment.content}{if $comment.img}

{/if}

{/if}

{lang_comment.reply} {$comment.relativeTime} {if settop} {($comment.is_top)?lang_comment.untop:lang_comment.top} {/if} {if $comment.user_id==uid} {lang_comment.delete} {else} {lang_comment.report} {/if} {$comment.liketimes}

{if $reply.touser}{$reply.author.username} {lang_comment.reply} {$reply.touser.username}{else}{$reply.author.username}{/if}:{@$reply.content}{if $reply.img}

{/if}

{/if}

{/each}